SOFTWARE SERVICES FOR INDUSTRIAL AUTOMATION

- DESIGN AND OPERATION PLC / HMI / SCADA

The PLC is the main computer of an automated system, where all the equipment communicate with each other. Programming is done according to the project, first offline and then on the field, for the commissioning.

- PROGRAMMING AND START-ROBOT

Programming robots online is executed directly on the machine. The robot is programmed without the help of the OLP.

In some cases the robotic system uses the OLP's program and therefore the optimization of the process is done manually on site.

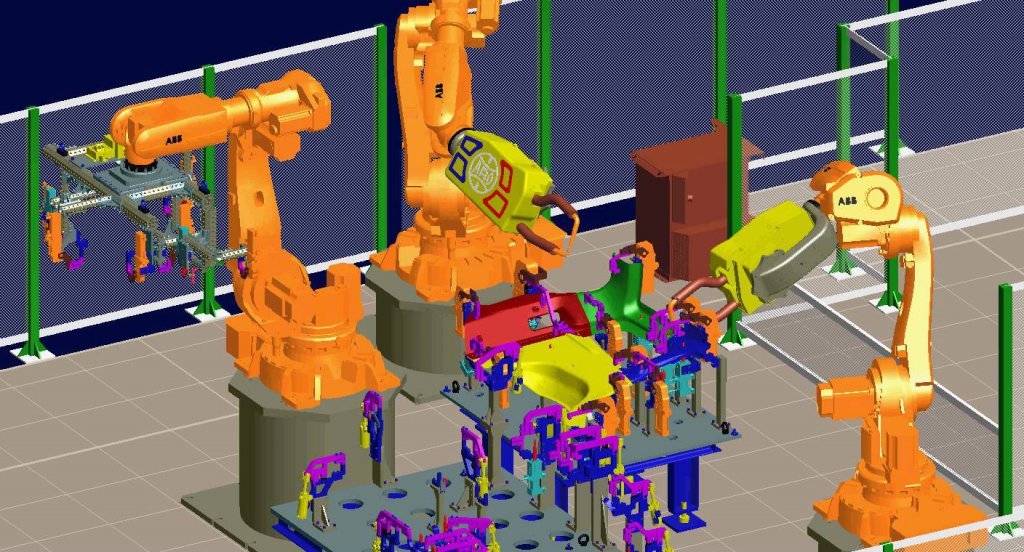

- PROCESS SIMULATION AND OLP

Offline programming allows control of the process and the feasibility stage of the plant design.

Moreover the paths of simulated robots, will be used as the root for online programming.

•robot offline programming (OLP)

•feasibility study / reachability

•simulation of the production process

SOFTWARE

•PROCESS SIMULATE

•ROBCAD.

Robot programming and commissioning.

Main robots:

•ABB

•COMAU

•FANUK

•KUKA

•PANASONIC

Applications:

•arc welding

•spot welding

•material handling

•gluing

•Interpress handling

PLC, HMI, S.C.A.D.A. software design.

Main systems used:

•SIEMENS

•ROCKWELL